CNG cast ductile iron HDPE Coupling

Product Introduction

HDPE couplings, also called HDPE pipe joint coupling,it is connection of the HDPE pipes.It is easy installation,saving cost..Each coupling include four bolts to make machined teeth into the outside of the HDPE pipe.

When the teeth effectively grip into the pipe,it provides a secure and rigid mechanical connection with pressure capabilities exceeding that of the HDPE pipe itself.The banks of teeth are positioned away from the gasket to enhance the gasket’s sealing ability throughout the operating temperature range.

The HDPE coupling also provides a low profile contoured housing with ramps along the outside diameter.This allows the coupling to slide over most obstacles when long length of the pipeline are relocated.

Key attributes

(1).Technical:Casting

(2).Shape:Round

(3).Color:Orange,Red,Blue, Galvanized available.

(4).Material:ductile iron ASTM-A536 Grade 65-45-12

(5).Standard: ANSI, ASTM, ISO

(6).Surface :Painting,epoxy,hot dip galvanized

(7).CNG gaskets are designed to provide life-of-the-system service in a wide variety of applications.

Gasket type : EDPM , temperature range : (-34----+110℃)

SILICON , temperature range : (-40----+177℃)

NITRILE, temperature range : (-29----+82℃)

Neoprene, temperature range : (-34----+82℃)

Fluoroelastomer,temperature range : (-29----+149℃)

(8).Customized packaging

(9).Application area:

①Civil and municipal constructions like water supplying, gas supplying, heat supplying, etc.

② Industrial pipeline system on shipping, mine, oil field, textile, powder plant, etc.

③Pipeline system on subway station, railway station, airport, seaport, bridge, etc.

(10).Payment terms:T/T or L/C

(11).Delivery time:Within 30 days or as per customers’ requirement.

(12).Brand name:CNG

(13).Port:Tianjin,China

(14).Customized support:OEM,ODM

(15).Working Pressure:300PSI

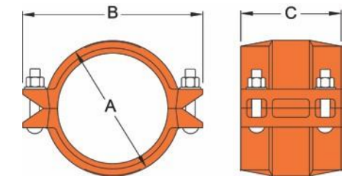

Size Specification:

| PIPE O.D. | Dimensions | Bolt | ||||

| Min. | Max. | A | B | C | No. | Size |

| mm | mm | mm | mm | mm | mm | |

| 50 | 50.5 | 70.7 | 111 | 105 | 4 | M10×55 |

| 63 | 63.6 | 86.7 | 128 | 105 | 4 | M10×55 |

| 75 | 75.7 | 97.5 | 140 | 105 | 4 | M10×55 |

| 90 | 90.9 | 113 | 156 | 105 | 4 | M12×75 |

| 110 | 111 | 136 | 180 | 112 | 4 | M12×75 |

| 140 | 141.3 | 167 | 210 | 118 | 4 | M12×75 |

| 160 | 161.5 | 187 | 230 | 118 | 4 | M12×95 |

| 180 | 181.7 | 211 | 253 | 118 | 4 | M12×95 |

| 200 | 201.8 | 228 | 290 | 127 | 4 | M16×90 |

| 225 | 226.4 | 261 | 330 | 127 | 4 | M16×90 |

| 250 | 252.3 | 279 | 345 | 134 | 4 | M16×110 |

| 280 | 281.7 | 312 | 391 | 134 | 4 | M20×120 |

| 315 | 317.9 | 247 | 428 | 134 | 4 | M20×120 |