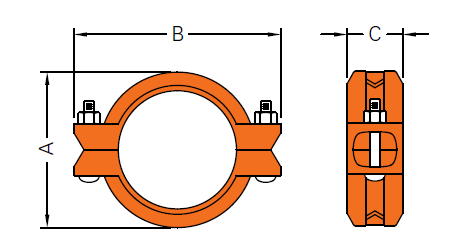

Style 1GS Rigid Coupling

Product Introduction

Rigid grooved couplings are intended for applications where rigidity is required. This type of couplings is a substitute for traditional flanged or weld joints. Rigidity is obtained through grip teeth in the housing, which permit slightly more movement in the joint than Angle Pad couplings.

Rigid coupling is a T&G(tongue & groove)design rigid coupling for moderate pressure applications where rigidity is required including valve connections,mechanical rooms,fire mains and long straight runs.The built-in teeth and T&G mechanism firmly grasp the pipe ends to eliminate undesired .Support and hanging requirements correspond to ANSI B31.1,B31.9 and NFPA13.

•Model 1GS rigid coupling socketed & meshing design

•Female and male port socket design is not easy to make the horizontal and horizontal seal twists

and turns,the gasket is not exposed,increasing the sealing and improve the overall service life of

the joint

•Enhanced body resists 4 times working pressure.

Read and understand all instructions before attempting to install any products.

Always verify that the piping system has been completely depressurized and drained immediately prior to installation, removal, adjustment, or maintenance of any products.

Wear safety glasses, hardhat, and foot protection. Failure to follow these instructions could result in death or serious personal injury and property damage.

The Style 108 ® FireLock™ IGS™ Installation-Ready™ Rigid Coupling shall be used only in fire protection systems that are designed and installed in accordance with current, applicable National Fire Protection Association (NFPA 13, 13D, 13R, etc.) standards, or equivalent standards, and in accordance with applicable building and fire codes. These standards and codes contain important information regarding protection of systems from freezing temperatures, corrosion, mechanical damage, etc.

These installation instructions are intended for an experienced, trained installer. The installer shall understand the use of this product and why it was specified for the particular application.

The installer shall understand common industry safety standards and potential consequences of improper product installation. Failure to follow installation requirements and local and national codes and standards could compromise system integrity or cause system failure, resulting in death or serious personal injury and property damage.

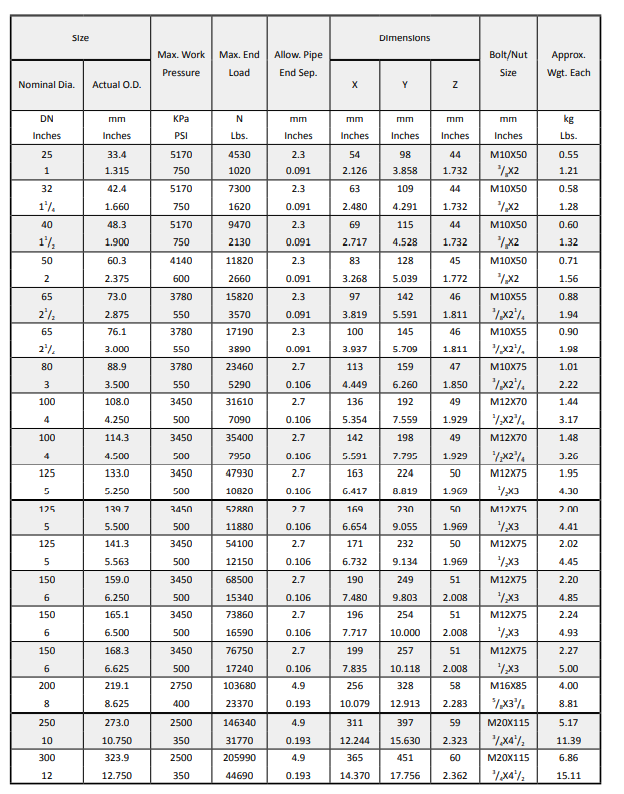

Size Specification

Light-duty rigid couplings are the short style of the rigid couplings, which are mainly used for grooved pipeline connection. At the joint part, the adjacent pipe ends are not allowed to have relative angular displacement and corresponding axial rotation.